Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

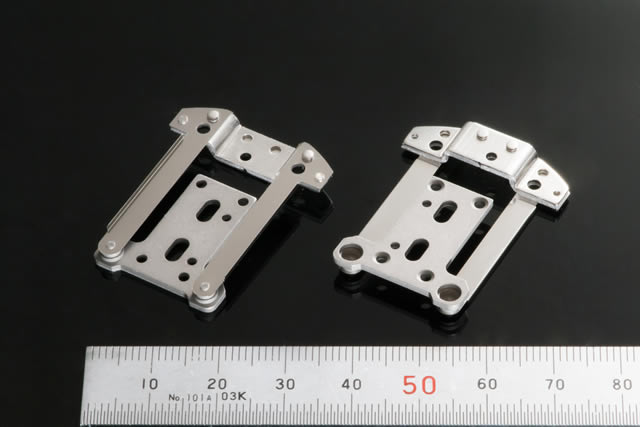

Metal stamping is a complex manufacturing technique that forms the base of all the automotive industry equipment. To be precise, more than 80% of all the primary parts of automotive components making up a vehicle are shaped and designed by the metal stamping procedure.

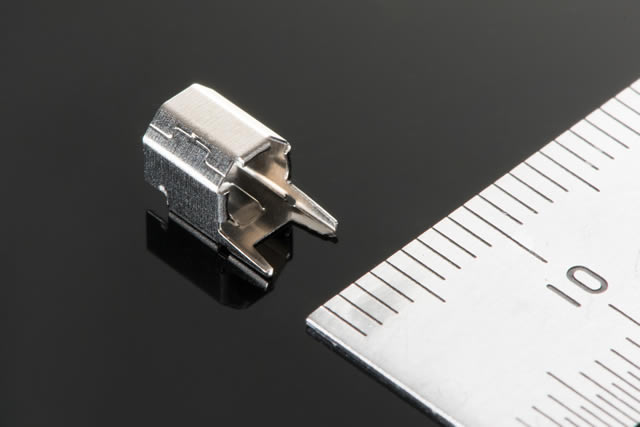

No wonder the metal stamping manufacturers have an unparalleled significance in the manufacturing industry, but that’s not all they are famous for. Other than automobile terminals, metal stamping is also widely used for making various different components belonging to many different industries, like shrapnel for the defense, medical instruments for medicine and healthcare, hardware for industrial manufacturing, and new energy hardware for electronic industries, etc.

(Copyright photo from: https://unsplash.com/photos/qo87H99BGto)

Four Types of Metal Stamping Techniques

Precisely, there are four different types of metal stamping techniques that are used to manufacture complex shapes and designs of different sizes that are utilized in various industries:

1. Progressive Die Stamping

Progressive stamping is a unique type of metal forming technique, which incorporates different metal modification methods such as punching, bending, coining, cutting, embossing, and more. These metal modification steps take place at various workstations, each of which shapes a different part that is utilized in multiple industries and applications. Most importantly, metal stamping manufacturers admire this manufacturing process for its high volume production. Also, its metal cutting and pressing are ideal for manufacturing small components of higher speed rates.

2. Transfer Die Stamping

Transfer die stamping is similar to the progressive die method, but the distinction occurs when the engineered parts need to be shifted to a different station to undergo other metalworking techniques. That’s when a transfer die employs a mechanical transfer system so that the parts can get processed by the press as an individual unit. In other words, the piece is free from the metal strip, and all the different cutting and pressing operations at various stations occur independently. Significantly, metal stamping manufacturers admire this manufacturing technique for its medium to high volume production traits favorable for manufacturing larger-sized parts to be processed at rapid speed.

3. Four-Slide Stamping

Four-slide is an integrated metal stamping technique, operating on four different axes following a moving mechanism of four tools that maintain the striking slides. Further, the four-slide machine cams control the order of these slashing slides to design the desired shape of the processing part. Metal stamping manufacturers are fond of this technique for its high precision products, versatility in intricate designs, and sophisticated small part fabrication from metal coils or wire.

4. Compound Stamping

Unlike the four-slide method that operates in multiple striking slides, the compound stamping works the opposite entirely because it takes only a single strike for compound stamping to accomplish numerous cuts, bends, and punches to shape the part simultaneously. Metal stamping manufacturers are fond of its quick and accurate manufacturing quality. Moreover, it is suitable for small, simple, and flat pieces in a medium to high production volume.

Considerations of Selecting a Metal Stamping Manufacturer

Here are some pointers to get you one step closer to your ideal metal stamping manufacturer:

1. Technology and Certificates

When considering one of the best metal stamping manufacturers to produce quality products for you, begin with authority and creditability. Search if your selected metal stamping company has any specialized technologies and certificates or recognition certificates for their outstanding manufacturing quality. Some qualified and experienced metal stamping manufacturers also display their patent certifications to restrict others from duplicating their specific designs.

2. Product Quality and Accuracy

As mentioned above, advanced technology is crucial for quality part production; hence, make sure to double-check check your metal stamping company is well-equipped with precision machinery sets for accurate and consistent production outcomes. Plus, the latest automated CNC machines are ideal for manufacturing complex shapes and sizes, which could give you great benefits, especially if your parts demand intricate designs with high precision and tight tolerance levels.

3. Manufacturing Technique

Another thing to be aware of is the technique your selected metal stamping company uses to manufacture your ordered products. It would be helpful if you realized that there are many metal stamping techniques, and they all have different tools that work in various ways. Thus, the method used in manufacturing, along with the material, decides the final lead time and product stability.

4. Customized Service and After-Sales Service

You must pick the metal stamping company that understands your unique project specifications and deals with them accordingly. Concerning that, accompany you with the best after-sales services in case you might need their assistance in improving a specific part design or size later.

5. Delivery Terms

Ever since the pandemic, there have been many rules and regulations that metal stamping manufacturers have to follow before any product reaches out to the owner. Whether they are precautionary protocols or any delivery limitations, thoroughly read your metal stamping company’s instructions due to pandemic restrictions.

One of the Best Metal Stamping Manufacturers under the Pandemic

After going through all the factors you need to consider before picking out your perfect metal stamping company partner, you might have already painted a picture of what your ideal manufacturer should have in terms of honorifics. If you wonder who might have all these specific traits and where you will find them, we have a perfect recommendation to make it more exciting. Yes, it’s the only metal and automobiles stamping manufacturer – Hashimoto.

We have a strict and effective epidemic prevention and control protocol, which every employee is forced to follow. Not only that, but we also have a governmental support policy encouraging metal stamping manufacturers to continue producing and exporting quality products under specific preventive measures.

Conclusion

It’s time to further tell you about the leading metal stamping company with an eminent background of 19 incredible years in the industry – Hashimoto. We specialized in metal stamping and mold manufacturing and thus provided everything, ranging from distinctive mold designs to accurate metal stamping mass production.

Our exceptional after-sales services leave no room for any further complications you might need to face; instead, we will actively follow up until you are satisfied with your final product.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox